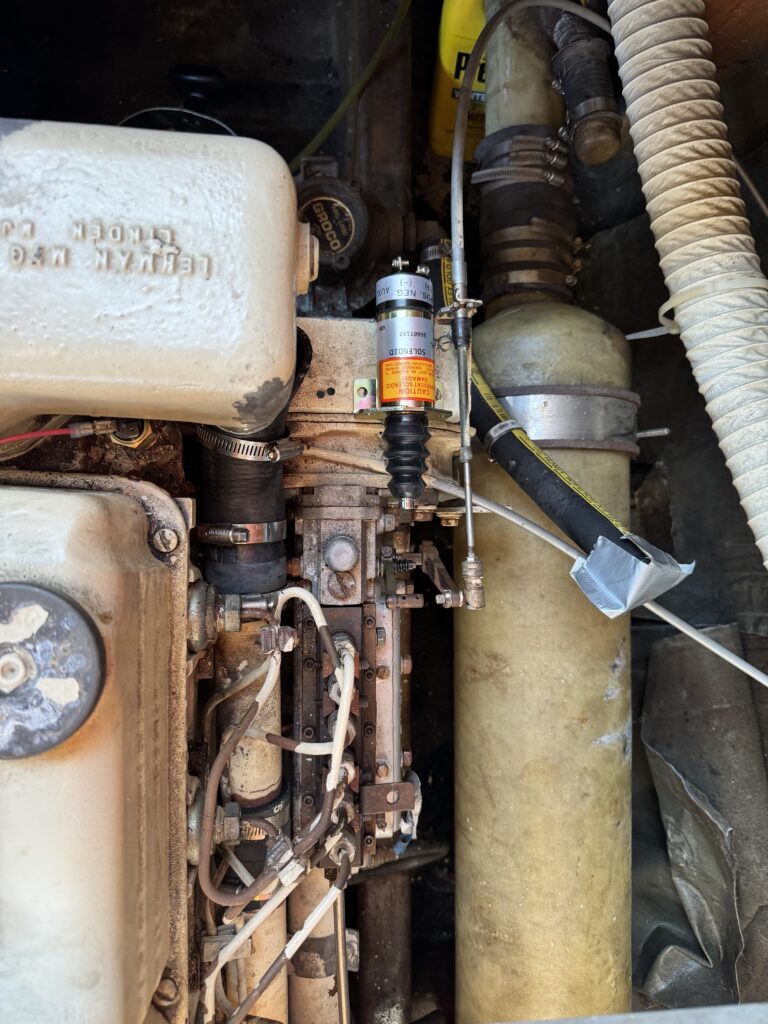

A broken shut-off solenoid

At some point, I’ll do my best to document out trip down the coast as it was one hell of an epic adventure… but I think I want to start by documenting the issues we’ve fixed as a way to get things down while they’re still relatively fresh in my mind.

In a nutshell, when we were trying to get the boat out Sacramento, we ran into a series of problems, but one problem has turned out to be an expensive blessing-in-disguise.

In a nutshell, we had started both of our 1972 Ford Lehman engines up with no issues a few times and then on the morning we were ready to start our adventures to SoCal, of course one of the engines wouldn’t start.

Mike, the mechanic helping me out, fairly quickly diagnosed that the short-off solenoid was no longer firing, so there was no way to get fuel into the engine.

Of course, trying to find a replacement for a 50 year old solenoid, turned out to be one hell of an adventure and the end result was that we learned from a “Lehman” guy out of Georgia, that my grandpa had put the shut-off solenoid in a particularly bad place to begin with. The Lehman guy predicted that by having it right before the high-pressure injectors, we were likely causing air to get sucked back into the engine every time we shut the engines off…

In a nutshell, the guy from Georgia predicted a key problem that has plagued these engines since the beginning, which is that I’ve heard lots and lots of people bitch about how they constantly need to bleed the engines.

We simply got a hose made that bypassed the solenoid and for the duration of our trip down the coast, we manually shut the engines off via a lever that’s directly on the engine. It’s not ideal to not be able to turn the engines off from the cockpit area, but it was certainly better than trying to solve a problem that didn’t have an obvious solution.

It turns out that once we started shutting the engines off via the lever, we never had to bleed the engines again. Bless his heart for all the amazing work he did on this boat, but one thing my grandfather apparently screwed up was in they placement of the shut-off value.

Once we were settled in Marina del Rey, I tasked a mechanic with add a new shut-off solenoid system… and in this case, it’s a solenoid that physically pulls back the lever that we had been manually using. Here’s what the new shut-off solenoid looks like on the engine.

One thing this required us to do was to add a kill switch to the dashboard.

I really wanted to have the cut-off switch fire when we moved the ignition to “off”, but the mechanics gave me a ton of reasons that this would never be possible. We tried buying a different ignition switch (at their recommendation) that included an “auxiliary” position (to the left of “off”) that was suppose to kill the engine, but this did’t work either. I kinda forget why, but it seems the auxiliary caused the switch to “not” fire… or something odd like that.

Anyway, at the end of the day, the mechanics recommended that we cut two more holes into the dash (one for each engine) and add a push button to kill the engines. That way, it would automatically turn itself back off right after each use and couldn’t be left “on” the kill position. However, I was hesitant to cut into the dash and still not convinced I won’t be able to find a mechanic who can get our new shut-off solenoid to work with the ignition switch.

The end result is that we used two currently unused levers on the dash as our new kill switches (labeled “ENG OFF”).

For people familiar with running the Avalon, I think they should be glad to know that I’m pretty sure we’ve cleared up two long-standing issues that we related to air in the fuel-injectors.

- It seems like we don’t have to bleed the engines any more… at least not on a regular basis as I’ve heard from others.

- The boat seems to idle really well bow. I also heard complaints that the boat would often turn off at low idle. I suspect that was because there was some residual air in the injectors due to the placement of the shut-off solenoid.